Zvinhu Zvinokanganisa Kusvika kweWelding Robots

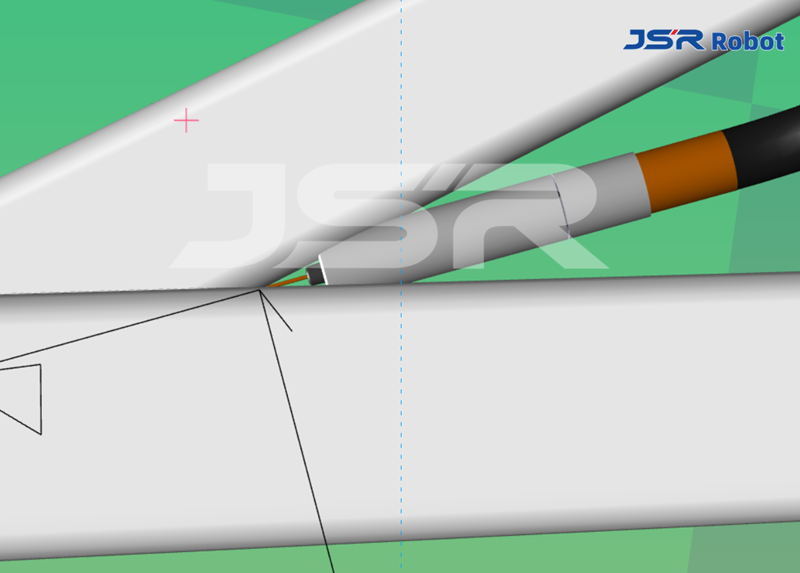

Munguva ichangopfuura, mutengi weJSR akanga asina chokwadi kana workpiece yaigona kugadzirwa nerobhoti. Kuburikidza nekuongororwa kwemainjiniya edu, zvakasimbiswa kuti kona yeworkpiece haigone kupindwa nerobhoti uye kona inoda kuchinjwa.

Welding marobhoti haakwanise kusvika kumakona ese. Hezvino zvimwe zvinofurira:

- Madhigirii eRusununguko: Welding marobhoti anowanzo ane 6 madhigirii erusununguko, asi dzimwe nguva izvi hazvina kukwana kusvika kumakona ese, kunyanya munzvimbo dzakaoma kana dzakavharirwa welding.

- End-Effector: Saizi uye chimiro chetochi yewelding inogona kudzikamisa huwandu hwayo hwekufamba munzvimbo dzakamanikana.

- Nzvimbo Yebasa: Zvipingamupinyi munzvimbo yebasa zvinogona kukanganisa kufamba kwerobhoti, zvichikanganisa makona ayo ekushongedza.

- Kuronga Nzira: Iyo robhoti yekufamba nzira inoda kurongwa kudzivirira kudhumhana uye kuve nechokwadi chewelding mhando. Dzimwe nzira dzakaoma dzingave dzakaoma kuwana.

- Workpiece Design: Iyo geometry uye saizi yeworkpiece inokanganisa kuwanikwa kwerobhoti. Complex geometries inogona kuda yakakosha welding zvinzvimbo kana akawanda magadzirirwo.

Izvi zvinhu zvinokanganisa kushanda uye kunaka kwerobhoti welding uye zvinofanirwa kutariswa panguva yekuronga basa uye kusarudzwa kwemidziyo.

Kana chero shamwari dzevatengi dzisina chokwadi, ndapota taura neJSR. Isu tine ruzivo uye nyanzvi mainjiniya kuti tikupe iwe mazano.

Nguva yekutumira: May-28-2024