Robhoti reindasitiri inorongeka, yakawanda manipulator yakagadzirirwa kufambisa zvinhu, zvikamu, maturusi, kana midziyo yakasarudzika kuburikidza neakasiyana akarongwa mafambiro nechinangwa chekuisa, kuburitsa, kuunganidza, kubata zvinhu, kurodha muchina / kuburitsa, welding / pendi / palletizing / milling uye mamwe mabasa ekugadzira. Iwo anoshandiswa mumitsara yegungano uye mamwe maapplication ekugadzira, pese panoda kubatwa zvinhu.

Mukupindura kubvunza kwevatengi nezve marobhoti welding, JSR inokutora iwe kuti uongorore marobhoti welding, uye zvakanakira & maitiro akajairwa anoshandiswa mukuita.

Chii chinonzi robhoti welding?

Iyo otomatiki yewelding process nemarobhoti ndeye robhoti welding. mabhobhoti anoita uye kutarisira welding mabasa kwakavakirwa purogiramu uye vanokwanisa reprogrammed maererano nechinangwa project.Robots akakodzera yakakwirira-vhoriyamu uye anodzokororwa mabasa.

https://www.sh-jsr.com/robotic-weldiing-case/

Robhoti welding inoshanda sei?

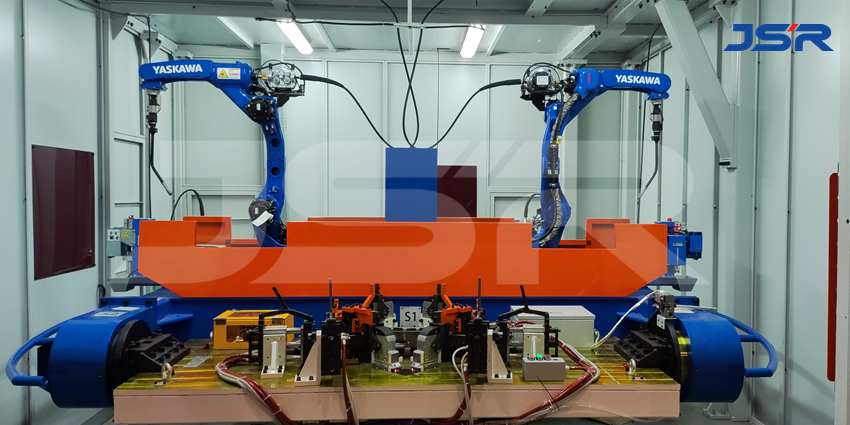

Welding marobhoti, kunyanya, anosanganisira ruoko runokwanisa kufamba mumativi matatu uye welding simbi pamwechete. Pane wire feeder inotumira filler wire kurobhoti, uye torch inopisa kwazvo yakananga kumucheto kweruoko inonyungudusa simbi panguva yewelding process.Engineers anochengetedza marobhoti uye anopa mirayiridzo kwavari.Pane control cabinet, iyo mushandisi anoshandisa kudzora zvirongwa zverobhoti.A wire feeder inopa imwe simbi waya kuruoko uye torch sezvinodiwa.

Mukuwedzera, iyo welding robhoti yekushandira inogona kuve yakashongedzerwa nemichina yewelding, nzvimbo, njanji yepasi, pfuti yekuchenesa zviteshi, laser michina, arc nhovo, etc. JSR inopa yakagadziridzwa welding yekubatanidza mhinduro zvinoenderana nezvinodiwa nevatengi.

Ndezvipi zvakanakira marobhoti welding?

mhedzisiro chaiyo, kupambadza kushoma, uye kuchengetedzwa kwakavandudzwa,Kuvandudza mashandiro uye kutonga nguva yekuendesa zvakanyanya.Marobhoti aya anogona kusvika kunzvimbo dzisingasvikike nemaoko emunhu uye kuita mabasa akaoma kunzwisisa zvakanyanya.

Ndeapi ma common welding process?

TIG Welding, MIG Welding, MAG Welding, ARC Welding, Spot Welding, Laser Welding, Friction Welding, Stud Welding, SAW, nezvimwewo.

Kune akawanda marudzi e welding process. Kana iwe uine chero mibvunzo, ndapota tizivise nezve yako workpiece zvinyorwa uye zvinodiwa. JSR mainjiniya anokupa mhinduro dzehunyanzvi uye masevhisi ekugadzirisa.

Nguva yekutumira: Zvita-21-2023